IHR Solution

HOT RUNNER SYSTEMS AND CONTROL UNITS FOR PLASTIC INJECTION MOULDS AND PRECISION MECHANICAL MACHINING

iHR Solution was founded in 2013 with the desire to make the experience gained in the various plastic sectors (automotive, consumer goods, toys, medical, packaging, technical), available to its customers. These experiences were first collected by the founders of the company and then shared with the different business teams.

Passion, transparency and consistency are imprinted in the company’s genetic code and are the real guiding principles that allow the company to face every project and challenge together with its customers every day. Customers who thus become partners with whom to work side by side to create new and innovative solutions for the world of hot runner systems and the processing of plastic materials.

IHR,

THE STRENGTHS ARE:

iSystem – Screwed hot runner injection systems

iHR Solution screwed hot runner injection systems can be used for a

wide range of applications, from standard systems to special systems, designed to meet every customer

need.

iHR technology includes a wide range of tips, such as the patented Topless T version, which guarantees fast

color changes, excellent mechanical performance of the moulded polymer and low operating pressures.

Among the other advantages of the iHR Solution systems, which enable modern and reactive production management,

there are the reduction of energy consumption, the simplicity of installation, the reduced dimensions of the

shut off units and the savings in maintenance costs.

Screwed single nozzles

iHR nozzles are divided into 4 categories:

- Single standards

- Individual Eco-Line

- Individual mini-mould

Multi-tip

Thanks to the different solutions, iHR Solution is able to satisfy every type of request, from the most

economical solutions for the moulding of amorphous polymers in common use to high performance technical

polymers, guaranteeing an excellent finish at the injection point and eliminating possible losses of material.

Screwed single nozzles

iHR nozzles are divided into 4 categories:

Single standards

Individual Eco-Line

Individual mini-mould

Multi-tip

Thanks to the different solutions, iHR Solution is able to satisfy every type of request, from the most

economical solutions for the moulding of amorphous polymers in common use to high performance technical

polymers, guaranteeing an excellent finish at the injection point and eliminating possible losses of material.

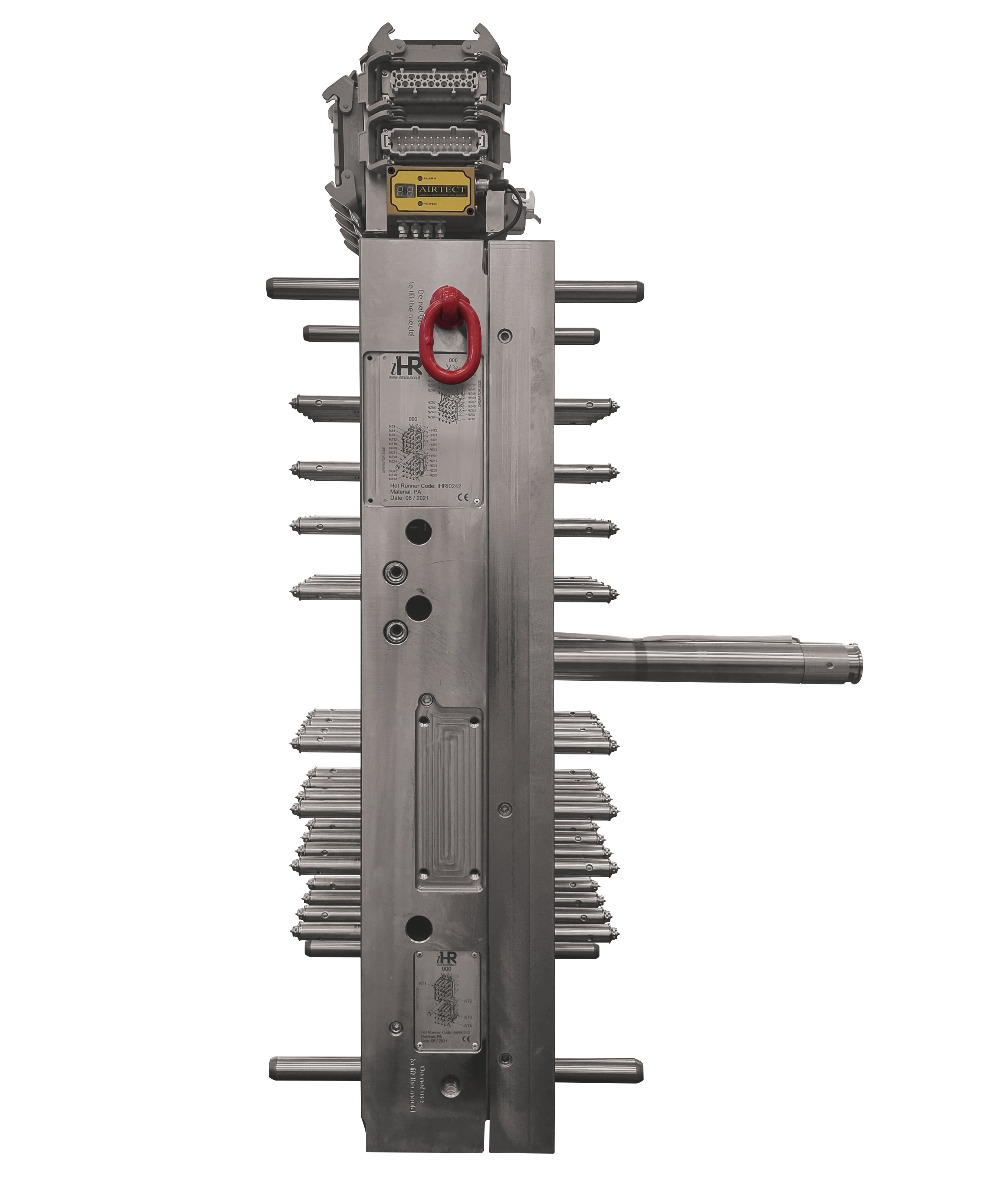

The HOT-HALF systems completely wired and ready for installation

For the multiple needs that emerge more and more urgently from the

world of plastic moulding, iHR Solution proposes Hot-Half Systems as an advanced interface with the mould, with

the possibility of integration in a specific design. iHR Solution Hot-Half Systems are fully wired, assembled

and tested, maximizing the performance of the systems. In this way, assembly times on the mould and subsequent

maintenance are reduced.

Based on the customer's needs, iHR Solution designs the best Hot-Half solution adaptable to any type

of mould base, avoiding any possible installation error.

The temperature control units, the pneumatic and hydraulic units for the control of systems with shut off injection

iHR Solution also provides the components related to the obturation

systems for the sequential management of pin closure, with the use of pneumatic or hydraulic solenoid valves and

pressure multipliers, in order to bring the correct operating pressure to the system.

The wide range of control units differs according to the production sector of the moulded parts,

thus allowing to carefully monitor the parameters of the application and the system used.

The temperature control units, the pneumatic and hydraulic units for the control of systems with shut off injection

iHR Solution also provides the components related to the obturation

systems for the sequential management of pin closure, with the use of pneumatic or hydraulic solenoid valves and

pressure multipliers, in order to bring the correct operating pressure to the system.

The wide range of control units differs according to the production sector of the moulded parts,

thus allowing to carefully monitor the parameters of the application and the system used.